Frequently Asked Questions

The Frequently Asked Questions (FAQ) section of emseal.com is continually being updated and is derived from questions asked through consultations with owners, architects, engineers, contractors, distributors and manufacturer’s representatives by phone as well as received through techinfo@emseal.com. Please let us know if your question is not adequately addressed here.

Q.Will liquid sealant primers affect BACKERSEAL? I am using BACKERSEAL as a secondary sealant to Dow Silicone. I need to prime the substrate with Dow 1200 primer. As I brush the primer onto the substrates will the primer adversely affect the BACKERSEAL?

No. We are not aware of a primer that will adversely affect BACKERSEAL during normal application. Specifically, the BACKERSEAL will not be affected by the Dow 1200 primer.

Q.Your data sheet claims that the material “exerts a backpressure” and “self expands to fill the joint”—what does this mean?

This means that the material, after compression to any point in its stated compression movement capability will recover unaided to any point in its claimed extension movement capability.

Why does this matter?

This is critical when evaluating a particular products capability to meet expected movements in a given application. If, for example, you have determined that the structural expansion joints in your building must accommodate 100% (+50% and -50%) of mean temperature joint size movement, then you want assurance that the product you select to provide watertightness will be capable of this amount of movement.

Closed-cell foams, as a general rule, suffer about 25% compression set. This means that after repeated cycles, particularly when combined with heat at levels equal to those achievable in actual substrate conditions (up to 185 degrees F), the foam loses forever about 25% of its original size. This translates into insufficient foam to fill the joint throughout the movement range and therefore loss of watertightness.

Q.Your materials are certified to be “stable” at 185 degrees F. What do you mean by “stable”?

Stable means the material will not bleed when held at this temperature. By “bleed” we mean that the impregnation emulsion in the foam will not drip, ooze, or otherwise be released from the foam matrix nor will it travel or be absorbed into the pores of porous substrates like brick, concrete block, concrete, stone, etc.

It should be noted that temperature stability is not meaningful unless it is linked to claimed movement capability. This is because as temperature rises, joints get smaller. As joints get smaller, the material installed into the joint gets squeezed.

It is critical to relate temperature stability in precompressed foam sealants to movement capability. EMSEAL certifies that its materials will not bleed at 185 degrees F throughout the movement capability claimed for each product.

If a product claims 100% of nominal size movement capability, unless otherwise specifically stated, it must be able to compress 50% and extend 50% from the nominal size.

Given that the compression of the material will occur as the result of the joint closing, and given that joint closing is caused by the expansion of structure during heating, it is logical to expect that the material will be stable at the combination of the expected temperature AND at the degree of compression at the minimum movement claim.

For example, SEISMIC COLORSEAL has a movement capability of 100% of nominal size. This means that 2-inch nominal material can squeeze down to 1-inch (-50%) and extend to 3-inches (+50%) in repeated cycles.

The impregnation in SEISMIC COLORSEAL is stable at 185 degrees F when squeezed to 1-inch as well as at any lesser degree up to 3-inches.

All of EMSEAL’s materials are certified to be stable at the temperatures claimed when compressed to the minimum of their claimed movement capability. IN ADDITION, all of EMSEAL’s materials are certified that they will recover unaided to the maximum of their claimed movement AFTER being heated and compressed as described above.

Some manufacturers claim stability at a given temperature but state no related degree of compression. Others claim stability at a given temperature and at, say, “20% compression”. This vague qualification usually means “when compressed down 20% from its uncompressed dimension.” The combination of high temperature and compression to this low level will never occur in the field.

Q.What are the typical lead times for EMSEAL’s parking deck, plaza deck, stadium, and floor products?

Average 4.5-days ex-factory for straight runs and order-specific when we are factory-fabricating transitions and terminations (see EMSEAL LEAD TIMES for more specifics).

Q.What are the typical lead times for EMSEAL’s pre compressed foam products?

Q.What is “compression set”?

Compression set is permanent deformation remaining after release of a compressive stress. Compression set is expressed as the percentage of the original material thickness after the compressive force is removed.

For practical purposes in joint sealants, compression set is the amount of the original size of the material that is permanently lost after compression or cycles of compression over a temperature range that the product will likely see in normal use.

Q.Why use impregnated foam backing–Why not use closed-cell backing?

This very logical question was asked, explored, tested and answered by EMSEAL decades ago. Closed-cell foams are cheap and if they worked to provide a comparable alternative to impregnated precompressed sealant, why wouldn’t we use them instead? The bottom line is they don’t work as a backing to moving, structural expansion joints.

Closed-cell foams suffer greater compression set than high-quality impregnated foams. Closed-cell foams are therefore not suited to structural, moving, expansion joints. Compression set is worsened by rise in temperature. At expansion joints, as temperature rises, building elements expand causing the expansion joint gap to close down. This means that the material installed into the gap is being squeezed and heated at the same time–the perfect conditions to cause compression set. Closed-cell backed alternatives to EMSEAL’s microsphere-modified-acrylic impregnated, foam look on their faces to be similar. The backing is their considerable shortcoming.

Permanent compression set in a closed-cell-backed look-alike results after just a single 3-hour cycle with the material compressed to 1½” and heated to 150°F (i.e. -25% of nominal size per movement claim at a very commonly experienced summer substrate temperature). The result is that in applications to which this product is offered, when the joint opens up again as temperature drops and the material is asked to extend to +25% of its size according to its offered movement, this product would go into tension at the bondline and within the fragile closed cells of the foam backing material. The resulting failure will be characterized by the rupturing of the closed cells at the bondline and resulting tearing of the silicone coating.

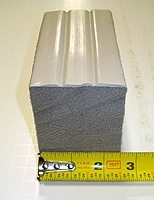

Closed-cell-backed hybrid shown at supplied size of 2-1/2″ (65mm) for compression into a 2″ (50mm) joint opening.

Closed-cell-backed hybrid shown at supplied size of 2-1/2″ (65mm) for compression into a 2″ (50mm) joint opening.

Permanent loss to compression set of 25% of the movement capability of the product after just one cycle to the published minimum joint size and simultaneously heated to a substrate temperature that will cause that movement.

Permanent loss to compression set of 25% of the movement capability of the product after just one cycle to the published minimum joint size and simultaneously heated to a substrate temperature that will cause that movement.

Q.Why does EMSEAL discourage the use of gutters under deck expansion joints?

There are several reasons not to use gutters under joint systems:

- The gutter conceals any leaks. The leaks go undetected. The structure corrodes. Once water (carrying salts and other corrosion causing chemicals) has bypassed the primary joint system, costly and dangerous degradation of the structure begins. This is because water runs over the concrete on its

way to the gutter. During this passage it will make its way to the rebar. The rebar will corrode, expand, and spall the concrete.

way to the gutter. During this passage it will make its way to the rebar. The rebar will corrode, expand, and spall the concrete. - Gutters are not water proofing, they are water management. Water that reaches a gutter must be managed to drains. To do this gutters must be pitched to ensure drainage. The gutters must be dammed at ends and be fabricated to be watertight at plane and direction changes. Joint systems are too often detailed in cross-section only. In cross-section a gutter looks effective. Joints detailed in cross-section will not get constructed either with pitch or with terminations, transitions, or integration into the drainage systems.

It is when the gutter is considered in 3-D that the challenges of water management are revealed. (More on 3-D joint design). - A joint system that incorporates a gutter as standard equipment or a joint design that incorporates a gutter beneath another joint system is by default admission that the joint system is not watertight. The choice of that joint system should be reconsidered.

- Gutters, or gutters incorporated into joint systems, provide a highway for vermin. It is not unusual, particularly in sports venues like stadiums to find evidence of active communities of rats and other vermin using gutters as their homes and/or transportation infrastructure around the building. Joint systems that are not watertight at the surface allow liquids (beer, soda pop) and washing-water-diluted foods to enter the gutter system. Vermin take advantage of this food source.

- Downspouts get blocked. Downspout are highly susceptible to blockage due to the accumulation of debris in gutters.

- Again, gutters conceal leaks. EMSEAL supplies joint systems that are watertight. These systems when properly detailed using isometric CAD details for watertight treatment at terminations and transitions, and when installed according to EMSEAL’s instructions, can be expected to be watertight.

If a system leaks, we want immediate, early detection of the leak. This will allow the cause of the leak to be identified and remedied. Gutters can seriously compound the difficulty of tracing the source of the leak to a particular location.

If gutters are used, however, it is critical to ensure that:- continuity of seal in the gutter material is assured at splices, terminations, and transitions in plane and direction,

- that regular inspection of contents of the gutters is prescribed as a routine maintenance procedure,

- regular inspection and cleaning of downspouts is undertaken to remove blockages

- that sufficient slope is engineered and constructed into the gutter to facilitate drainage,

- that water collected in gutters is managed to drains or other exit points where runoff does not facilitate deterioration of structural components or finishes,

- that the gutter is not concealing deterioration of structural elements above.

Q.Are your deck joints ADA compliant?

Yes.

For more information read this article: “Expansion Joints, ADA and Spiked Heels–Where do you stand?“

Q.Can EMSEAL provide job specific drawings based on field conditions?

Yes.

EMSEAL can aid in the approval process by providing product drawings based on job specific, existing conditions communicated to EMSEAL by the contractor.

Field sketches, measurements, digital photographs and modified construction details, combined with information gathered using our checklists as a guideline, form the basis of the information communicated to us to supply supporting CAD files and illustrations for use by the contractor in their production of shop drawings. EMSEAL typically produces illustrations of engineered products in place as well as watertight transitions between planes.

The extent of the drawings depends also on the product, application, and complexity of the field conditions but as a rule, as long as all the parties involved in the project are willing to work together to problem solve within their area of responsibility, there are seldom conditions that cannot be properly addressed.

Our local representatives and distributors are at your service as are our on-staff technical team. This link will give you representative and distributor contact information and the EMSEAL technical team can be reached at techinfo@emseal.com, toll free at 800-526-8365 or by calling 508-836-0280.

Q.On your interior floor expansion joint index, what do Standard / Medium / Heavy relate to?

Standard / Medium / and Heavy as they relate to load ratings are provided as a subjective guideline in making a preliminary narrowing of product selection for a given application.

”Standard” is meant to suggest for use in light duty uses such as typical office or other spaces where pedestrian traffic or occasional rubber-wheeled traffic like mail carts and light-weight cleaning equipment, luggage, etc. is the normal traffic. The systems in this category are usually comprised of extruded aluminum rails, either surface or blockout-mounted, into which a light duty elastomeric insert is installed.

“Medium” suggests applications where occasional heavier maintenance equipment (scissor lifts, motorized cleaning equipment etc.) would be added to the standard traffic. The systems in this category are comprised of slightly heavier aluminum extrusions, for either surface or blockout mounting, with heavier extruded rubber inserts, or of lightweight all-aluminum construction.

“Heavy” is for applications where truly heavy loads (forklifts and other vehicles), or high-point load vehicles (gurneys, mobile medical equipment, coin carts, materials handling equipment, etc.) are the norm. These systems are heavy-duty, all-aluminum extrusions of extraordinary quality and fit. They are capable of multi-directional movements and are also available in surface or blockout mounted variations.

In these cases, since the actual loads and pressures the joint system feels are directly related to the type of wheels, combined with the gross weight of the vehicle, we provide detailed loading information as can be seen on the product page for the FS 110 system.

We are working to provide the information in the format seen on the FS 110 page for all our heavy duty profiles but are not quite there yet. If there is a model that appears more suitable to your application that does not have enough information we would be pleased to assist in comparing a particular vehicle load to any of our systems. This Interior Floor Expansion Joint Checklist is a handy way of communicating your needs to us.

Q.Does your DSM SYSTEM support high heel foot traffic?

While the DSM SYSTEM is likely to be more durable than alternatives under foot traffic including contact with incidental high heel point loads, we cannot provide assurance that it will be any better in preventing all possible mishaps resulting from a wearer’s failure to take responsibility of their choice of wardrobe and its suitability in traversing joints and other surfaces typical of normal walking surfaces. (see also ADA and Spiked Heel tech bulletin).

Q.What is the coefficient of friction on the SJS SYSTEM Coverplates?

Initial Dry SCOF: 1.176

Initial Wet SCOF: 0.936

The ADA recommends that horizontal surfaces have a SCOF (Static Coefficient of Friction) of at least 0.6. Consequently, the SJS coverplate passes the recommendation both the wet and dry.

Tests were conducted according to ASTM C-1028 by an independent testing lab, AMT Laboratories, on stainless-steel coverplates with a standard sand-blasted finish. The same finish is supplied on our aluminum coverplates and the values are therefore expected to be the same.

The values stated are for the initial SCOF. As with any coverplate, the surface may wear over time. It is the responsibility of the property owner to maintain an ADA compliant SCOF.

(For a pdf of the test report CLICK HERE)

Q.What is Emseal Used for?

Emseal is used to fill, seal and bridge building expansion joints in commercial construction applications. Emseal is the company name. Emseal manufacturers a comprehensive line of products for use in sealing not only large structural expansion joint openings (movement joints) but also building component connections.

In addition Emseal manufactures precompressed, self-expanding, impregnated foam sealants for use in gasketing applications in numerous industrial, automotive, building, and other original equipment manufacturer (OEM) applications. And, Emseal manufactures products for use in bridging and sealing expansion joints on bridges. Emseal is also used in applications where the joint sealant is continuously immersed in liquid. Emseal has products developed and used it acoustic sound-dampening applications as well.

Structural Expansion Joints: Emseal products are purposely designed to fill and seal the gaps designed into building to accommodate movement. In order for these gaps to effectively isolate sections of the building from one another, the expansion joint must completely bisect the building. In doing so a literal gap is created through all of the building materials–the concrete foundation, walls, split-slab plaza decks, parking decks, floors and roofs. The waterproofing materials installed onto or over these building elements are similarly interrupted by the expansion joint opening. This means that water will leak where the respective waterproofing membranes are installed unless the joint opening is properly sealed. The expansion joint is a gap through the below-grade waterproofing membrane; the air/water barrier on the walls; the traffic-bearing deck coatings; the insulation; the roof membrane; and any fire proofing. Consequently the function of those building elements must restored at the expansion joint opening. Emseal is used to ensure continuity of seal, continuing of insulation, continuity of fire proofing at all interrupted waterproofing systems.

Each of Emseal’s structural expansion joint products are designed to integrate into the adjacent materials to ensure the proper performance of the entire building envelope.

Q.Does the EMSHIELD DFR2 require a sealant band injected from the underside along the silicone bellows-to-substrate interface?

No. The EMSHIELD DFR2, fire rated, watertight, traffic durable, expansion joint system was deliberately tested to UL 2079 without silicone-sealant injected at the bondline from the underside. The system passed UL 2079 with no problem in this configuration. The goal of the DFR2 project was to produce a fire rated expansion joint that could be installed entirely from the top side of a deck without the need to access the bottom side. This goal was achieved.