Selection Guide: Fire-Rated

Fire rated expansion joints that waterproof, insulate, block sound, handle traffic and movement in a single product.

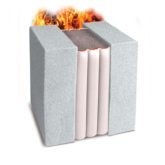

Fire-Rated Interior and Exterior Wall

Description

- Watertight and fire rated

- 2-Hour, built-in fire-rating (UL 2079)

- Seals both sides of joint

- Many industry colors

Details

1/2″ to 6″

(12 – 150mm)

100% Movement (+50%/-50%)

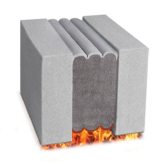

Description

- Watertight and fire rated

- 3-Hour, Built-In Fire-Rating (UL 2079)

- For concrete, concrete block or gypsum walls

- Many industry standard colors

Details

1/2″ to 6″

(12 – 150mm)

50% Movement (+25%/-25%)

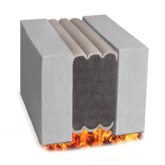

Description

- Watertight and fire rated

- 1-Hour, built-in fire-rating (UL 2079)

- Seals both sides of joint

- Many industry standard colors

Details

1/2″ to 6″

(12 – 150mm)

100% Movement (+50%/-50%)

Description

- Pick-resistant

- Watertight and fire rated

- 2-Hour, built-in fire-rating (UL 2079)

- Seals both sides of joint

Details

1/2″ to 6″

(12 – 150mm)

100% Movement (+50%/-50%)

Fire-Rated Deck and Floor

Description

- 2 -Hour, Built-In Fire-Rating (UL 2079)

Details

1/2″ to 4″

(12 – 100mm)

100% Movement (+50%/-50%)

Description

- 3-Hour, Built-In Fire-Rating (UL 2079)

Details

1/2″ to 4″

(12 – 100mm)

50% Movement (+25%/-25%)

Description

- 1 or 2-Hour, Built-In Fire-Rating (UL 2079)

- Integral coverplate

- Non-invasively anchored

Details

2″ to 10″

(50 – 250mm)

100% Movement (+50%/-50%)

Description

- pick resistant floor joint

- 3-hour, built-in fire-rating (UL 2079)

- non-invasively anchored

- joint face adhered

Details

1/2″ to 4″

(12 – 100mm)

50% Movement (+25%/-25%)

Description

- pick-resistant floor joint

- 2-hour, built-in fire-rating (UL 2079)

- watertight

- non-invasively anchored

- joint-face adhered

Details

1/2″ to 4″

(12 – 100mm)

100% Movement (+50%/-50%)

Fire-Rated Split Slab and Plaza Deck

Description

- For fire-rated, split-slabs, plaza decks, podium decks

- 2-hour built-in fire-rating

- Watertight integration with deck waterproofing membrane

Details

up to 4″

(100mm)

max. mean join

100% Movement (+50%/-50%)