RVS–Recreational Vehicle Sealant Tape

Product Innovation:

EMSEAL RVS RV Sealant Tape features a breakthrough in sealant technology. The innovation comes in the composition of the acrylic adhesive infused into the cellular foam base material. This new proprietary chemistry incorporates a hydrophobic/hydrophilic component never before available in a sealant formulation.

The result is a material that features sealing performance significantly greater than any acrylic-impregnated predecessor. In addition, it is odorless, clean handling, UV stable, non-staining, and highly versatile.

Product Description:

EMSEAL RVS Sealant Tape is a preformed expanding tape seal. RVS is made of a resilient cellular foam infused with a hydrophobic, modified-acrylic, liquid adhesive sealant which is then compressed to a sealing density level appropriate to the application. The result is a hybrid sealant that features the best characteristics of foam and liquid sealants while eliminating their respective weaknesses. RVS compresses uniformly without overspill to provide a lasting seal.

Available in a wide variety of configurations, recreational vehicle manufacturers determine the size of RVS suited to their specific applications and performance needs.

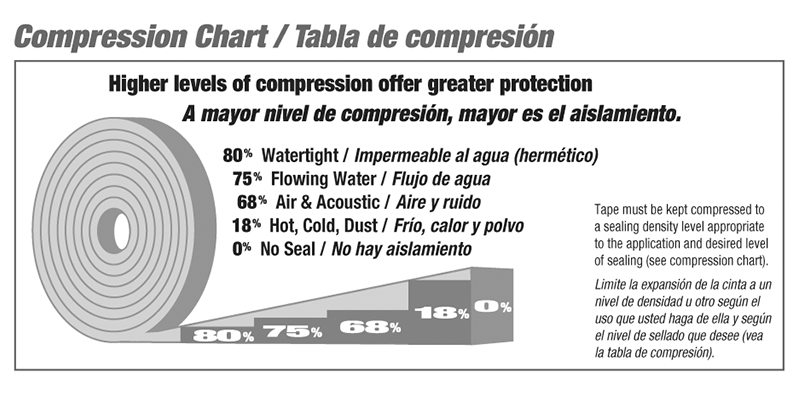

Sealing between the RVS and body components is a result of the foam’s cell structure, the impregnation, and the appropriate degree of compression. EMSEAL RVS is packaged precompressed in rolls. The material contains a pressure sensitive mounting-adhesive on one face to facilitate installation.

Uses and Applications:

RVS is an effective seal against water, vapor, air, sound, dust, allergens and vibration.

RVS is suitable for use on painted or unpainted metal, plastic, glass, wood, or other surfaces, as well as between dissimilar materials.

For applications requiring high temperature stability.

Ideal as a gasket tightly squeezed between joint faces that are mechanically fastened together such as in window and trim applications.

In applications where damping vibration and noise is as important as weather sealing.

As a secondary seal behind liquid sealant.