Precast Sealant Tapes and Joint Systems

Sealing Telecomm Shelters

Telecommunication shelters must be watertight. Liquid sealant (caulk), alone, is not protection against long-term water infiltration. Backing up the caulk with UST Impregnated Sealant tape will provide lasting protection. Not only do telecomm shelters house critical electronics, but telecomm shelters are usually located at the full mercy of the weather. Extremes in heat, cold, as well as pummeling from rain, snow, sleet and driving winds leave these critical structures totally exposed.

In the highly competitive market of telecomm shelter manufacturing, a watertight, maintenance-free sealing solution is an essential offering.

Product Description

UST is a preformed expanding foam tape sealant. It is made by impregnating a resilient, high-density, open-cell polyurethane foam with water-based, stabilized acrylics. It is supplied factory precompressed and packaged in reel form with self-adhesive backing for use in preformed joints subject to expansion and contraction movement, and also as gaskets in tightly squeezed, non-moving joints.

After removal of packaging, material begins gradual expansion–slowly in cold weather, faster in hot.

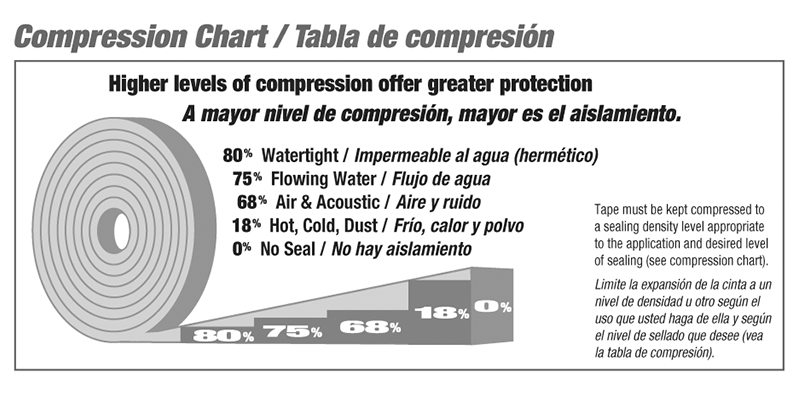

Sealing ability is a function of the characteristics of the open cell foam structure, the level of impregnation, and the degree of compression or density which can be varied to suit specific applications. For example, lower compression serves for dust, driving snow, etc., while progressively greater compression is required for vertical run-off water, etc.

UST is supplied precompressed to less than the nominal material size for easy insertion into a preformed joint of the same opening width.

Sealing between the foam and substrate is achieved through a combination of the pressure-sensitive adhesive impregnation and the back pressure of the expanding foam.

Why liquid sealants alone are not a watertight solution

While they provide aesthetic benefit, liquid sealants (caulk) lose effectiveness for many reasons:

- poor initial adhesion to exposed aggregate

- poor adhesion caused by dust and concrete particles

- failure to create “hour-glass” required for proper liquid sealant performance

- failure to tool sealant to promote proper adhesion

- loss of key physical properties (UV resistance, modulus) over time and temperature.

Furthermore, structures sealed with liquid sealants must be recaulked as an ongoing maintenance commitment. This is difficult and extremely costly given the often remote location of these units.

For these reasons, providing a secondary seal of impregnated foam sealant will ensure that leaks do not occur even when the caulk fails.

Liquid sealants (caulking) are widely misused. They do not work to fill voids, cannot function if too much is used, and cost manufacturers a fortune in wasted material. UST does fill voids and can be used to control liquid sealant depth thereby eliminating waste and ensuring a geometry that will allow the liquid sealant to function.