Adhesion in Tension

In tension is the weakest way to use an adhesive, yet the principle on which many expansion joint and sealant technologies rely for their performance. Adhesives are best used in shear or in combination with a mechanical force. The more durable joint sealing technologies rely either on adhesives in shear as in “membrane/nosing” type products, or use inherent compression to diminish or eliminate adhesion in tension on the bond line as well as within the sealant or adhesive material itself. More on ‘tensionless’ hybrid sealants.

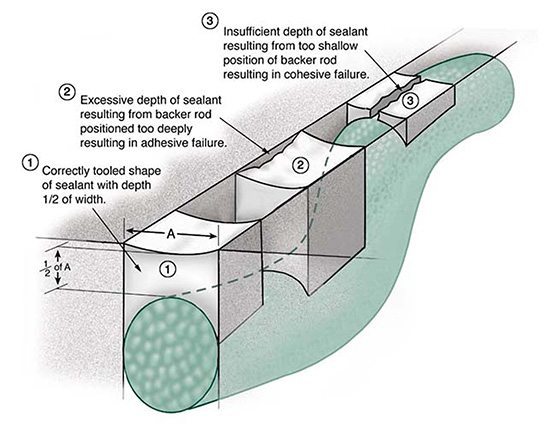

Adhesion in Tension in Liquid Sealant & Backer Rod:

Figure 2: Effect of Adhesion in Tension on liquid sealant (caulk) performance during joint opening as the result of positioning and sizing of backing material and correct shaping of sealant. Image Copyright © Emseal Joint Systems Ltd. All rights reserved.

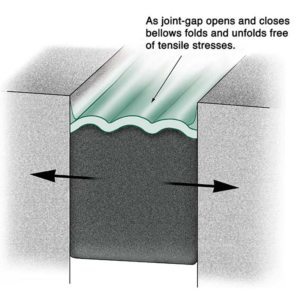

‘Tensionless’ Hybrid Sealant:

![]()

Images Copyright © Emseal Joint Systems Ltd. All rights reserved.

NOTE: The definitions of terms and terminology herein are rooted in the context of use in the field of construction-related joint sealing in EMSEAL’s experience. They are provided with the intent of offering a fuller understanding of the context of their usage. Any suggestions or questions regarding interpretation are welcome and should be directed to content@emseal.com. Thank you.