Emshield DFR / WFR CE

CE Marked, EN-1366-4 Certified Movement Joint

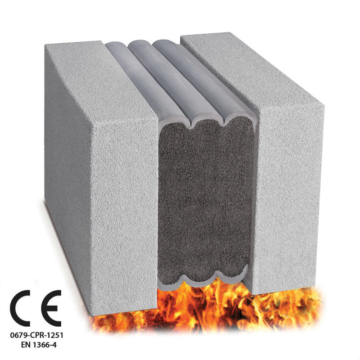

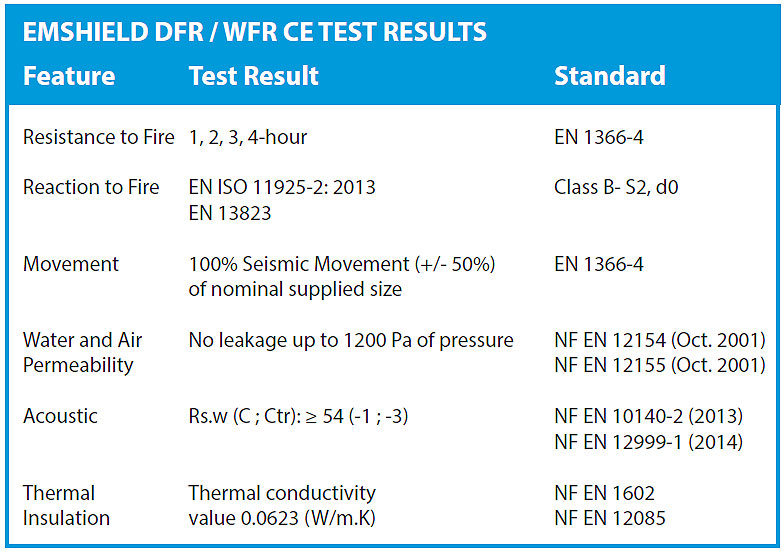

An EN-1366-4 tested, fire-rated movement joint, Emshield DFR / WFR CE is a silicone-faced movement joint for European and other markets requiring CE marking. Tested by CSTB France and certified by European Technical Assessment (ETA), Emshield DFR / WFR CE provides up to 4-hours of fire resistance, and is a water, air, and smoke seal with 100% movement capability. Other features include thermal insulation, UV stability, and trafficability. In contrast to fire barrier blankets Emshield DFR / WFR CE is installed entirely from above the floor slab and performs without the need for invasive metal anchors or complex field fabricated assemblies. Emshield DFR / WFR CE provides a cost effective, long-term watertight seal.

Emshield DFR / WFR CE combines a factory-applied, low modulus silicone with an open cell polyurethane foam infused with a water-based, fire-retardant, acrylic dispersion. The traffic-grade silicone facing is factory adhered to the infused foam on two sides at a width greater than the maximum anticipated joint extension, and is then cured. When compressed, the silicone facing forms a bellows profile capable of accommodating +/-50% (total 100%) movement from the product’s nominal size. The bellows fold, and unfold during movement virtually free of tensile stresses.

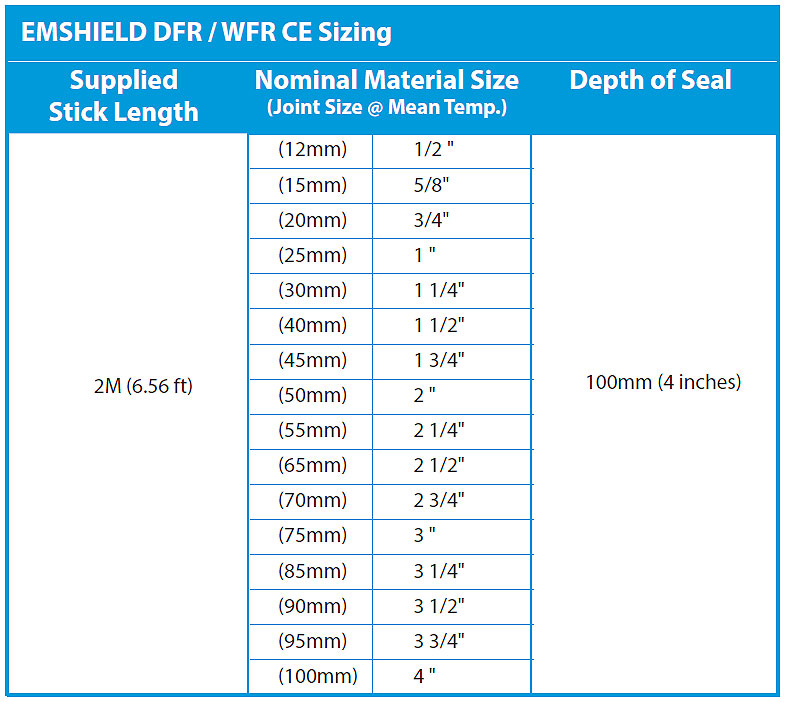

Emshield DFR / WFR CE is supplied precompressed to slightly less than its nominal size for ease of installation. To install sticks, clean the substrate faces, apply supplied epoxy adhesive to the substrates. After removing packing materials insert the Emshield DFR / WFR CE into the joint. After the Emshield DFR / WFR CE has expanded to fill the joint space and is adhered to the substrates, a field-applied silicone corner bead ensures a watertight seal at the substrate interface.