Compression Set and Foam Selection in Expansion Joint Sealants

Foam-based expansion joint systems are commonly used to accommodate building movement while maintaining reliable continuity of seal. However, not all foam materials perform equally under long-term compression, temperature changes, and repeated joint movement. One of the most critical factors influencing performance is compression set.

This article explains what compression set is, how it affects joint performance, and why material selection, particularly closed-cell versus precompressed, acrylic-impregnated open-cell foam, matters in movement-capable expansion joints.

What is Compression Set?

Compression set is the permanent loss of a material’s ability to return to its original thickness after being compressed. In expansion joints, this reduces the foam’s backpressure, the force that maintains continuous contact with the joint faces as the joint opens and closes.

Compression set is accelerated by:

- Repeated compression and extension

- Elevated temperatures

- Sustained compressive strain

These conditions are typical in structural expansion joints exposed to daily thermal cycling and seasonal temperature extremes. Over time, compression set can reduce the effectiveness of the joint seal and limit the material’s ability to accommodate movement.

Closed-Cell Foam: Advantages and Limitations

Closed-cell foams, such as ethylene vinyl acetate (EVA), are often used as backing materials due to their low cost and ease of fabrication. However, under typical construction conditions (e.g. cyclic movement and temperature fluctuations) closed-cell foams can develop permanent compression set.

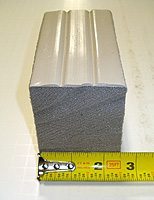

For example, laboratory testing shows that a closed-cell EVA-backed joint seal compressed from 2‑1/2″ nominal size to 1‑1/2″ at 150°F for just three hours exhibited about 25% permanent compression set. While the seal remained intact, its ability to fully recover during joint opening was reduced.

Consequences of compression set in closed-cell foam systems include:

- Reduced effective movement capability

- Increased stress at the bond line during joint extension

- Greater reliance on adhesives rather than compressive contact

- Sensitivity to installation tolerances and surface irregularities

Because of these limitations, closed-cell foam is generally unsuitable as the primary load-bearing component in joints that experience frequent or large movements.

Precompressed Open-Cell Foam: Performance Benefits

Precompressed expansion joint systems typically use acrylic-impregnated, precompressed open-cell foam. This material exhibits very low compression set, even under sustained compression and thermal cycling.

Key benefits include:

- Consistent backpressure throughout the movement cycle

- Ability to accommodate minor material relaxation without loss of seal

- Movement accommodation without placing the system in tension

Precompressed open-cell foam is therefore well suited for joints subjected to frequent, multi-directional, or long-term movement.

Selecting the Right Foam Expansion Joint System

When choosing a foam expansion joint system, designers should evaluate:

- Expected joint movement range

- Frequency and magnitude of thermal cycling

- Exposure conditions (temperature extremes, weathering)

- Long-term durability requirements

For applications involving structural movement, precompressed acrylic-impregnated open-cell foam offers predictable recovery, sustained backpressure, and consistent performance over time. Closed-cell foam-backed systems may be appropriate for limited-movement applications but carry a higher risk of performance loss due to compression set.

Conclusion

Compression set is a key factor in the long-term performance of foam expansion joints. Understanding how different foams behave under real-world conditions allows designers and building owners to select systems that provide:

- Reliable movement accommodation

- Sustained seal integrity

- Extended service life with minimal maintenance

By carefully considering material selection, installation, and expected service conditions, engineers can ensure expansion joints continue to perform effectively over the life of the structure.

"Economy" Joint Seal Composition

Compression Set in Closed-Cell "economy" Joint Seals

Approximately 25% permanent compression set observed after a single three-hour compression and thermal cycle. The resulting reduction in recovery limits effective movement capability and causes the system to enter tension at the bond line during joint extension. Test conditions: compression to 1-1/2″ at 150°F, representative of commonly experienced summer substrate temperatures.