2 Houston Center Plaza, Houston TX

Texas

Date: 2012

DSM-FP and SJS-FP Deliver Watertight Expansion Joints After Chronic Leaking

Plaza deck expansion joint sealing is no longer a mystery. How DO you stop leaks at plaza deck expansion joints? The plaza deck around 2 Houston’s iconic tower had always leaked and provides a representative case study of this common problem for property owners. This is because, like most plaza decks, the joints were treated at the structural level using a looped membrane — this “buried-band aid” approach to plaza deck sealing seldom lasts.

To address the problem, the owner hired consultant Stone Glazing Consultants to find a more permanent cure. The cure came in the form of the design, product selection and installation executed through a collaborative partnership between the consultant, the installer, LS Decker Inc, the membrane manufacturer American Hydrotech and Sika Emseal. This collaboration is grounded in pre-installation quality assurance — a process that identifies, designs solutions for, and addresses all of the unique conditions on the site that could possibly undermine a watertight installation.

The beauty of DSM-FP is in the simplicity with which it attaches to walls. Because the sealing element is the DSM System, it seals non-invasively to the wall side of the joint. This means no mechanically attached wall brackets, rails, screws, anchors, embeds or other hard-to-install invasive fasteners. The deck side features the FP (for plaza) retainer leg that holds the side flashing sheet for watertight integration into the deck waterproofing membrane.

Retainer-legs, flashing sheets, capping strips and all required components were factory-fabricated for this installation. Here you can see the side flashing sheets, before integration with the deck waterproofing membrane, following the bend in the joint. Factory-fabrication ensures continuity-of-seal and accelerates installation.

A change in the elevation of the slab on the wall side of the joint was easily addressed by first field-measuring the condition and then factory-fabricating the system to match the elevation change. Here the retainer legs have been coated with the DSM System epoxy just prior to installation of the precompressed foam seal. The side flashing sheets can be seen to be welded for continuity and are seen prior to integration with the deck waterproofing membrane.

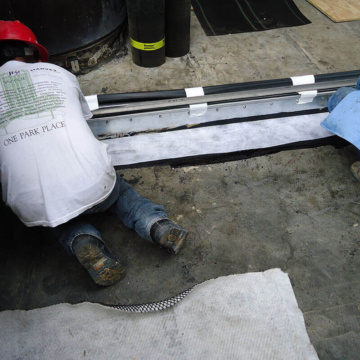

A fabric reinforcing layer of Hydrotech’s Flex-Flash F is commonly used in renovation/rehabilitation projects as additional protection. The fabric is embedded into the first coat of rubberized asphalt, Hydrotech’s Monolithic Membrane 6125® (MM6125®).

The DSM System is installed between the wall and FP legs on the deck side of the joint. Here you can see the method used for making joins between lengths of the DSM precompressed foam sealant. The ends of the material are held proud of the joint while the rest of the material is installed flush to the tops of the rails. The ends of the foam are then pressed simultaneously together in a “drawbridge” motion. This ensures that the join is in compression. The silicone applied to the face of the silicone bellows fuses the join to ensure watertightness.

DSM-FP installed on plaza deck on left side and wall of building on right side. Protection layer of Hydroflex 30 deck waterproofing system is seen at left.