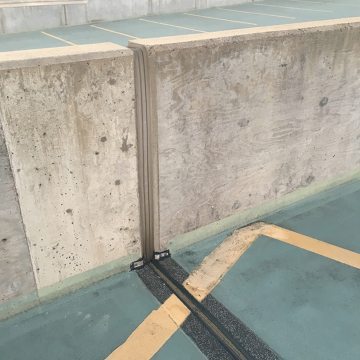

Thermaflex are blockout-mounted, watertight, winged compression seal parking deck and stadium expansion joint systems.

Each join is welded throughout the extrusion’s cross-section to ensure that the primary and secondary seals inherent in the system are watertight. (MCU Park, Coney Island, Brooklyn, NY)

Anyone can make an expansion joint watertight in cross-section. It is at changes in plane and direction and plane, and between different technologies that joints leaks. EMSEAL has cured this problem with custom-quick factory transitions and terminations made to fit field measurements.

Each weld is strengthened with a reinforcing band of welded thermoplastic rubber sheet and water-tested before it leaves the plant.

Factory-fabricated transitions and terminations are custom made for your job, are quicker to install than field fabricating them, and remove your anxiety from the responsibility for watertightness.

A follow-up visit to the USPTO shows how durable EMSEAL's Thermaflex system is. Even after 13 years Thermaflex is still functioning and looking like it did when it was first installed

A common place for leaks is Deck-to-Deck to Deck-to-Wall transitions EMSEAL addresses this leak point with a welded Santoprene sheet corner transition.

Seismic Colorseal-DS restores watertightness to unique transition to Thermaflex in a parking deck to a curb and parapet wall.

Dulles International Airport IAD parking expansion joints Thermaflex deck to column.

Inspection in June, 2004 of 8-year old THERMAFLEX nosing material at Ronald Reagan International Airport, Middle/North parking garage, shows localized shaving of low-aggregate-ratio nosing material to the right of the leading edge of the tire. Caused by errant snow-plowing the impact scarring is superficial and repairable and the joint remains watertight.

Loops of Santoprene thermoplastic rubber are welded to create shear pockets. This replaces the center cells of the Thermaflex expansion joint system to facilitate movement in a shear.

After factory fabrication each shear pocket is flooded with water and tested for leaks before shipping. Complex column transitions are common and are routinely addressed by Emseal.

Even at changes of plane and direction Thermaflex is durable and maintains continuity of seal after 20 years. The shear pocket both accommodates movement in shear conditions, it additionally facilitates transition in plane (from deck to curb in this instance).

Factory-welded "boot" terminations ensure Thermaflex parking deck expansion joints are watertight where they transition to Seismic Colorseal in columns, parapets, and walls.

Almost anyone can make expansion joints watertight in cross section, but it's at changes in plane and direction that joints leak. Sometimes you get changes in plane (upturn at curb) and direction (tee) in close proximity. That's when you want Thermaflex from EMSEAL. Welded to match field measurements, reinforced with welded santoprene reinforcing bands, and water tested before shipping, EMSEAL welds take the worry out of waterproofing.

Factory-fabricated, reinforced, leak-checked, winged expansion joint transitions for a parking deck. If you look closely you’ll note that the joint is a 6-inch seal teeing into a 4-inch seal at a column, then terminating in another 4-inch tee at the wall.

Anyone can make an expansion joint watertight in cross-section. It is at

Anyone can make an expansion joint watertight in cross-section. It is at